As the saying goes, “All work and no play makes jack a dull boy” My studio practice includes a strict regiment of play. Sometimes it is metaphorical; when I am engaged in a creative exploration where the intention is to try hard not to be self-critical of the outcomes. Other times, it is play!

My most recent play experience was a solo trip out to Clinton lake here in Lawrence. What started out as a leisurely two day camp, turned into a weekend research project on the performance of the Bamboo Canoe. The varying conditions on the lake this weekend were a perfect proving ground to study the characteristics of the canoe’s Rob Roy inspired shape.

Conditions on Thursday:

http://www.weather.gov/climate/getclimate.php?wfo=top

During gusty times, small white caps appeared making for an exciting ride. Moving down wind I was able to catch a few swells for a short ride on the surf.

In general I felt in control and balanced. Despite the wind, the boat tracked evenly, the key was to ballast the boat with the gear.

I was traveling with 40 Lb. pack. I found that tucked directly in front of me, with my legs wrapped around the pack, the boat felt even more stable (our center of gravity had to have been right at the waterline.)

When headed into the waves, there was a rare wave that would throw spray into the boat. My thoughts immediately moved toward designing a spray skirt that would extend the bow-deck. A design that could be clipped onto the stem band and then to the scuppers on the gunwales.

Friday, two neighbors moved into the next site. Highly enthusiastic about the boat, the were quick to overlook their original annoyance that I had arrive a day earlier to claim the picturesque site that perches wonderfully above the lake.

Mike and Marcos were keen on giving me feed back on the boat. On saturday, morning, the weather cleared and the warm condition tempted me into a swim. Before my departure, they each took a turn paddling, they helped me document a stability test, and with a gps they brought along, we were able to track my top speed on the water. On a short burst, I accelerated to 7.2 mph.

I’m hoping Mike and Marcos will drop me a link to the video they shot of the stability test.

I’ve been pushing hard on some new work getting ready for my next show at Wexler Gallery in Philadelphia. It opens may 7th, 2010. I’m also so honored to be able to say that this is a joint show with Tom Hucker (see link). Tom has been a hero to me for a while now, so I’m swelling with pride. I’m really excited about where the work is going, and have really made some technical changes/advances to the process in order to achieve the forms you see below.

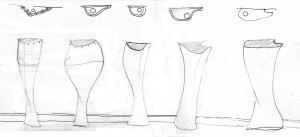

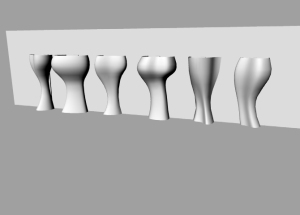

These came from a sketch that arrived in my sketchbook sometime toward the end of the canoe experience (while I was editing the video that documents the inspiration, construction, and launching of the canoe -see link below). A series of 6 forms were generated on a software program called Rhino, from which I was able to cut and print out cross section, similar to the canoe making process. The program generates each compound curvilinear surface from 4 bounding curves that I define. From there the process is similar to that of the construction of the canoe as documented in the video, with the following exceptions.

I’ve had to change the strip dimension. I’ve cut the strips in half to create a more square cross section, this allows each piece to bend more evenly in both directions.

I’ve introduced Hot Glue as a clamping mechanism, a trick that maker and artist Rob Macks of Laughing Loon Canoes showed me when I visited his studio. This replaces the wedging system documented in the video.

The bamboo was very clear in communicating it’s thresholds. I was able coax a bit more flexibility by creating a humidor and moisturizing the the individual strips. Steam bending would have worked as well, but not practical with this many strips!!!

I hope to have three cocktail tables to show together in May. I’ve chosen to do the three on the right in the rendering, primarily because it seemed like they would push the bending capacity of the bamboo strips in different ways – in wood working terms, bowed (warped along the length), crooked (warped along the edge), and twisted (like a Twizzler although my favorite sweets are Skittles).

Cheers,

Tom

Transitioning back into life at home has proven to be more challenging than transitioning into life at the CFC. The day-to-day is packed with myriad things that demand immediate attention. With young kids, long gone are the focused days of time in the workshop. But with the distance of time and space, I’m still left with a feeling of fondness and deep respect for the people and work happening at the Center. My fellow Fellows, were a huge part of my experience, and although I’ve alluded to their help on my project, their individual gifts and their work had an enormously positive impact on me.

To generalize, the care and dedication of all of these individuals was paramount. “Hard working” might be one way to describe what I witnessed, but it seems that the word “hard” implies both “difficulty” and “toil”. Both of these subsequent words are a bit askew when describing what I experienced. Although there were many elements to the work that was being done that I would certainly qualify as technically “difficult,”(and it is safe to say that all the Fellows constantly challenged themselves in this respect) it was most notable that the spirit with which the Fellows approached their work was one of zest and joy. If there was any element of “toil,” it was certainly met with an equal amount of “playfulness.”

If handwork were to be used as a metaphor, it is needless to say that I hope to keep in touch with them all, and that our friendship has the comfort, warmth and familiarity of a favorite pair of gloves.

I met Brian a few years ago and immediately admired his “centered” demeanor. In getting to know him better during this visit, I enjoyed the keen wit in his humor and the sincerity in his willingness to share and teach. His beautiful work and eye for design playfully incorporates marquetry and color. I came away remembering the importance of thinking deeply and acting confidently.

Reed is always cool and composed. His immense talent is also paired with a humility and graciousness. He is passionate about being a furniture maker, and with his focus I can only assume his future to be wherever he wants to take it. I know I’ll strive to emulate his drive and focus. I can only wish to have his Canadian bred slap-shot, which I got to witness during his first game of the season. Have Fun!

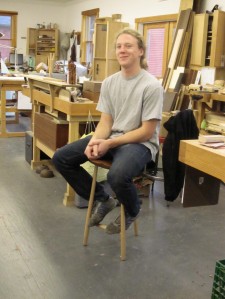

At 18, Tyler impresses me with his clarity and gift. His work has the beauty of a singular confident brushstroke. Although I never got a picture of the stool he’s sitting on, it is beautifully crafted and emerged seemingly effortlessly in just a short day and a half. The shaped seat is crisp and beautifully contoured like the Maine landscape which I hope we will hike together someday soon.

Vince made a life change recently. After 30 + years as a contractor, he dissolved his partnership in a successful business to follow a calling. He brings all of his construction experience to a new scale, and now as a furniture maker his eyes for detail twinkle with each stroke of his finely tuned Lie-Nielsen Shoulder Plane (which he graciously loaned to me on various occasions). His skill and talent are only surpassed by his willingness to try new things. I’m inspired by his approach to life and hope to continue evolving as he has.

The beauty of the CFC is in its small scale, the fellows were not the only people that impacted me during my time there. I was touched deeply by many; by their genuine interest, insight, wisdom, and care. I’d like to think that I’ve made lasting friendships, and hope to soon be reunited whether it be in the studio, across a handmade table, on a trail, or on the water in a canoe.

Filed under: Bamboo Canoe

Decks were fitted and brass screws placed through the walls of the hull and through the in-wales prior to glueing up the out-wales.

Two layers of varnish (for now...I'll complete 5-6 total before it's done.) and she's ready for the first float.

It’s been almost two week since my last post. It was a mad push. I had set a personal goal to float the BambooCanoe in Maine, and part of that goal was to float it with my two kids for the first time. The day after the last post, Shelli and the kids flew into Portland for a week-long visit. Basically, I had to get the boat suitable to float by Thursday the 22nd, because we had plans to drive down the coast for a weekend getaway on Friday the 23rd. So I’ve been finishing the boat late into the nights, and spending time with the family during the days…burning the candle from both ends. I’ve also been packing myself up to leave the Center for Furniture Craftsmanship, which I did on the 27th. Needless to say, its been an intense two weeks and in hindsight, quite an amazing month. I know this blog has been mostly about the BambooCanoe, but I have much to share about the amazing people I’ve been grateful to meet during my time in Maine, but I’ve had a few request to get more up about the boat. As I’m en route driving back to Kansas, I’m limiting this post to an update on the BambooCanoe. Please stay tuned to see the video of the first launching also. I’m having to reformat the video for up-loading.

Filed under: Bamboo Canoe

I’ve been getting a lot done in my time here. Since my last posting, I’ve finished glassing the exterior of the hull, and have flipped the canoe over to scrape and glass the interior.

Unlike the exterior, I’m only going to put one to two coats of resin on the interior. This will leave the weave texture of the glass raised for grip. While all of this was curing this past week, I’ve been starting in on the gunwales, thwart, decks, and the paddle.

I’ll have more pictures soon.

Filed under: Bamboo Canoe

The next step in the process is to sheath the hull in fiberglass. I’ve added a bottom plate of carbon fiber which will add rigidity and abrasion resistance to the bottom of the boat. It was also an aesthetic decision.

The process of mixing and applying epoxy resin is a bit tricky and I have to thank my fellow Fellows – Reed Hansuld, Tyler Killian, and Vince Scully for their help. Without them, I would have struggled to mix epoxy, apply epoxy, and document the process all at the same time.

Filed under: Bamboo, Bamboo Canoe, Center for furniture Craftsmanship, Furniture

My journey to Maine was long and relatively uneventful. I did however get a chance to visit with friends along the way. I’m fortunate to have the friends that I do, and I’ve already started to get to know the other Fellows here at the CFC. Two nights ago, we went out to a fantastic dinner at a restaurant in Camden, Maine called Francine’s. During our meal, Adam Peterson, a furniture maker from Minneapolis, Minnesota talked about the value of fine furniture as it related to the fine artisan meal we were consuming. He talked about the wonderful patrons that he’s had who have supported his craft. He commented that they truly value the experience of owning something made to a high level of refinement and care. I couldn’t agree more. In this day and age of instant and fast, the object that is carefully and well made, stands out. And to the discerning, it is worth every penny. After all, the experience of owning fine furniture is not exclusive to the original purchaser’s lifetime. It will long out live him or her. It will carry on functionally, but also build its own independent history. Isn’t that why it’s called an heirloom? It weaves us together, generation to generation.

Studio Fellowships at the Center allow for studio space, on-site materials for purchase, and 24 hour access to incredible woodworking facilities. In return, one is simply to contribute 6 hours of service time per week to the Center. This can include anything from being a gallery monitor, to lawn maintenance, to sorting lumber into the lumber racks. At the end of the day when you work side by side contributing, you quickly become a part of this wonderful community.

Filed under: Bamboo Canoe

Before I continue further into sharing my progress and process on the Bamboo Canoe, I need to state that most of my construction process is informed by Ted Moore’s fantastic book, “Canoe Craft”. In it, he does a very comprehensive job of describing the process of building a cedar strip canoe. It has been highly valuable in this journey, and I fully recommend it if you are considering building a canoe of your own. He includes information on how specific aspects of a canoe’s design perform in the water, and he touches upon the canoes’s rich history. He also describes several different models and includes brief descriptions.

My canoe is modeled after the Rob Roy (a solo, double-paddle canoe) that is described in his book. I chose this form for two different reasons. First, I already have an Old Town 164 (a 16′-4″ tandem canoe), I don’t need another tandem. And second, because of the form’s history. As Ted Moore’s describes,

“…the origin of the Rob Roy goes back to England and the mid 1800’s. John MacGregor, after seeing our native birch bark canoes and the Eskimo kayak, designed his idea of an efficient cruising canoe, calling it the Rob Roy. Typical of this type of solo canoe were: length 12′ to 15′, propelled with a double blade paddle from a sitting position and often rigged for sail. Early American canoe builders like J. Henry Rushton and W.P. Stephens were influenced by this style.”

For me, the fact that this form evolved from MacGregor’s cross-cultural experience is highly significant. In introducing a material (bamboo) that has such strong cultural connotations, I feel that I’m adding to the forms cross-cultural lineage.

After the planking is completed, the high spots or ridges are taken down with a block plane, spoke shave or sander. Because the grain of bamboo moves outward at each node, both planes and spoke shaves have a tendency to tear the fibers out. Fortunately, the Center for Furniture Craftsmanship (CFC) has a Lie Nielson Scraper Plane. It is an absolute joy to use. After scraping, the hull is sanded and “faired” to produce an even surfaced hull.

The next step is to fiberglass the hull…

Welcome to my Blog. I have to thank Whit Bones for helping me overcome the inertia of learning something new. As the name of the blog suggest, I hope to be posting about my on goings in the studio. However, I’m going to be formally starting this blog from Rockland, Maine. Yesterday, I arrived in Maine, settled into my apartment which I’m renting for the month and unloaded my car-full of materials and tools into my space at the Center for Furniture Craftsmanship. My first impressions of the CFC are that the students, faculty, and fellows are all warm, talented and willing to share. The facilities are top notch!!! I can’t wait to dive in and get to work. As you can see from the images I’ve already posted, I’m in the process of building a bamboo canoe. My plans for my time here will be to finish the canoe and develop ideas for some new pieces of furniture and sculpture that use some of what I’ve learned from the construction of the canoe. As I learn the technology involved with blogging, I’ll be posting pictures and hopefully some video. So please check in from time to time and join me on my (canoe) adventure.